Policy of PKOP LLP in the field of quality, fire safety, environmental protection and energy saving

2.1 Environmental Management System

2.2 Energy production from renewable energy sources

2.3 Protection of atmospheric air

2.4 Greenhouse gases

2.5 Use of water resources

2.6 Waste management

2.7 Financing of environmental activities

2.8 Environmental impact assessment

2.9 Production environmental control

2.10 Environmental insurance

2.11 Interaction with local population/div>

Environmental safety at production facilities is one of the priority tasks of the Company. By investing in the efficient environmental management, PetroKazakhstan builds infrastructure facilities that enable to improve the environmental situation at all production sites and adjacent areas.

In order to reduce the impact of production processes on the environment, every year the company allocates significant funds for environmental protection measures, implementation of the resource-saving technologies and processes that meet international standards and legislative requirements of the Republic of Kazakhstan.

PKOP LLP actively participates in social environmental projects. It carries out annual tree and vegetation planting campaigns in the territory of the refinery and sanitary protection zone.

Prevention of major environmental accidents, compliance with the requirements for air emissions, waste water and solid waste treatment, reduction, recycling and reuse of wastes are among the priorities of the company’s environmental protection activities.

In accordance with the Industrial Environmental Control Program, the inspections of the refinery facilities and instrumental measurements of environmental component status are carried out at PKOP LLP within the framework of monitoring of compliance with the established standards of maximum permissible emissions and discharges, as well as soil quality in the sanitary-protection zone of the refinery.

Within the frames of the modernization of the waste treatment facilities, an oil sludge processing unit was built and put into operation. Oil sludge processing is provided at the decanter unit with 3 phase separation of oil sludge with return of recovered oil products to the technological process. This activity allows preventing accumulation of oil-products in the sludge collectors of the enterprise, which also improves the environmental situation.

In 2019, the volume of return of treated wastewater and reused industrial effluents amounted to 882.721 thousand m3, including – 645,430 thousand m3 of effluents were returned to the fire fighting system. 184 mln KZT in equivalent for fresh water was saved. After the Deep Treatment units – ultra-filtration and reverse osmosis - 237,291 thousand m3 of treated wastewater were used in the form of makeup of the recycled water supply unit, which made it possible to additionally save an equivalent amount of fresh service water.

2.1 Environmental Management System

PKOP LLP developed, implemented, maintains and constantly improves the Environmental Management System (EMS). There is a certificate for compliance with the international standard ISO 14001:2015. The Policy of PetroKazakhstan Oil Products LLP in the field of quality, occupational safety, environmental protection, energy saving and energy efficiency improvement has been developed.

In order to implement the PKOP LLP Policy with regard to environmental protection, as well as to ensure environmental safety related to the impact on environmental condition of the region, every year PetroKazakhstan Oil Products LLP sets the goals and objectives for environmental safety. The surveillance and re-certification audits for compliance with the ICS requirements are carried out on a regular basis. Every year an analysis of EMS functioning is carried out; the quantitative indicators of EMS performance are reflected in the company’s reports.

The basis for EMS is application of a process approach that ensures continuous management and emphasizes the importance of:

- understanding and meeting the requirements

- need to consider processes in terms of added value

- achieving planned results

- continuous improvement of processes based on objective measurement

PKOP LLP:

- identified and applies the criteria and methods (including monitoring, measurement and related performance indicators), necessary to ensure the efficient functioning and management of processes

- identified and makes available the resources required for these processes

- allocated the duties, responsibilities and authorities with respect to these processes

- evaluates relevant processes and, if necessary, makes changes to ensure achievement of the intended results by processes

Considering that the relation between the ecological aspects and environmental impact is a link between cause and consequence, as well as that any environmental aspect relates to an element of the Enterprise’s activities, which may have an impact on the environment, the Enterprise has developed and maintains procedure DP-13-01-15 “Definition of essential environmental aspects” that defines the methodology for identification and determination of the significance level of the environmental aspects of the Enterprise’s activities.

Identification of the environmental aspects of activity, identification of essential aspects among them, assessment of their characteristics is carried out in order to determine the priorities of environmental activity of PKOP LLP, to develop environmental measures, to justify planned measures on negative impact reduction of PetroKazakhstan Oil Products LLP’s performance on the environment.

Identification of environmental aspects and identification of the essential ones among them is a continuous process that determines the past, present and potential impact of PetroKazakhstan Oil Products LLP’s activity on environment.

The results of the environmental aspects assessment are drawn up in the form of “Register of Essential Environmental Aspects”, which are the registered data of EMS, and serve the basis for development of the environmental objectives and programs.

Responsibility for the organization of the procedure for identification of the environmental aspects in PetroKazakhstan Oil Products LLP is assigned to the Department of Health, Safety and Environment, including the definition of essential environmental aspects; the formation, approval and communication to the Top management of “Register of Essential Environmental Aspects”.

An unscheduled review of the register of identified environmental aspects is carried out in the following cases:

- implementation of new or improvement of old processes

- mastering of new technologies or new equipment

- implementation of new products, new projects

- development of new types of raw materials, etc.

In order to comply with the law regarding the environmental protection, PKOP LLP monitors the legislation of the Republic of Kazakhstan and other regulatory documents and requirements applicable to the activities of the Enterprise.

Ensuring the legislative and other requirements applicable to the environmental protection activities is a part of the integrated management system of PKOP LLP. In this regard, a documented procedure DP-10-03 “Requirements of legislative acts and other requirements. Conformity Assessment” has been developed, implemented and is maintained, which establishes the procedure for identification and access to the legislative and other environmental requirements, as well as updating this information. All applicable legislative and other requirements were taken into account when developing EMS. On the basis of the adopted Policy, PKOP LLP guarantees their application.

PKOP LLP continuously brings to the attention of the relevant personnel, managed by PKOP LLP, and all concerned parties the applicable requirements.

According to DP-10-03 “Requirements of legislative acts and other requirements. Compliance assessment.”, PKOP LLP:

a) defined and ensured the access to undertaking of compliance with the legislative and other requirements related to environmental aspects

b) determined the manner in which the mandatory requirements are applicable to the enterprise

c) relevant mandatory requirements were taken into account in the development, implementation, functioning and continuous improvement of ICS.

The enterprise plans its further activities taking into account identified risks and opportunities (SWOT-analysis), essential environmental aspects (register of essential environmental aspects), assumed obligations (list of legislative and regulatory acts applicable to activities of PKOP LLP on environmental protection. The results of this planning are development plans, business plans, budget, and production plan.

In accordance with international standards ISO 14001, ISO 9001, OHSAS 18001, PKOP LLP has developed the following documented procedures:

- DP-13-06-10 Organization and conduct of internal audits of ICS

- DP-13-01-19 Organization of environmental control

- DP-20-01-20 Metrological support

- DP-13-06-30 Risk and opportunity management. SWOT analysis

- DP-13-06-04 Organization of external and internal communications

- DP-13-06-02 Inconsistencies. Corrective and preventive actions

- DP-13-06-01 Management of documented information

- DP-13-02-12 Emergency preparedness and response

- DP-13-01-16 Environmental safety management

- DP-13-01-17 Waste management

- DP-13-01-15 Identification of essential environmental aspects

- DP-10-03 Requirements of legislative acts and other requirements. Compliance assessment

- DP-11-27 Quality control of petroleum feedstock and petroleum products

- DP-02-02-09 Education and training of personnel

- DP-13-02-30 Requirements for PPE

- DP-09-22 Maintenance and operation of railway network infrastructure

- DP-13-02-13 Identification of hazards and risk assessment in the area of health protection and safety

- DP-07-08 Energy efficiency monitoring

- DP-07-07 Energy planning

PKOP LLP has developed and implements the process of monitoring and measurement of EMS processes in accordance with the requirements of procedure DP-13-01-19 “Organization of environmental control”. EMS processes are monitored and measured in order to assess the state of processes and to demonstrate their capability to achieve planned results. Monitoring results serve as source data for the development and implementation of the corrective and preventive actions.

Measurements of all indicators, important for environmental protection, are carried out by the refinery laboratory with the periodicity in accordance with the approved time - schedules.

Also, all measurements can be carried out by external organizations possessing the license for carrying out of such measurements, which are to be carried out both at the request of PKOP LLP, and at the request of external control organizations.

PKOP LLP has an instrumental measuring base both for monitoring the quality of crude oil and oil products, and monitoring the parameters of production processes.

Metrological support of production is carried out at PKOP LLP to ensure reliability of measurement results.

All measuring instruments shall undergo:

- periodic calibration or verification

- adjustment and alignment

- maintenance and repair

Storage and operation of monitoring and measurement devices provides protection against damage and unauthorized interference in their operation.

In case of revealing the failure of monitoring and measurement devices, they are to be removed from the places of use, and the results of measurements, which were carried out using such monitoring and measurement devices, are to be re-checked using the serviceable equipment. The results of repeated measurements and monitoring shall be documented and registered. Faulty monitoring and measurement devices are to be repaired or replaced.

Documented information on calibration, maintenance, and measurement results is to be maintained in working order.

Registration of these monitoring results is regulated by the requirements of the applicable regulatory documentation. All information on the results of monitoring is systematized in the Environmental Team.

In the regions of production activity of PKOP LLP there is no local population, leading traditional way of life.

2.2 Energy production from renewable energy sources

In order to implement the Energy Saving and Energy Efficiency Improvement Policy, as well as to reduce emergency situation through strict compliance with ST RK ISO 50001-2012 Standard requirements, PetroKazakhstan Oil Products LLP has set itself the following objectives:

- Reduce consumption and rational use of energy resources: ensure industrial safety, increase industrial control efficiency over observance of energy consumption requirements.

- Reduce risks connected with energy resource consumption by using and implementing up-to-date energy saving equipment and technology.

- Exercise a control over energy consumption, exclude groundless expenses, enhance economical efficiency, productiveness and improving the equipment operation procedures, and motivating and training of personnel.

Since 16.07.2019, a solar power plant was put into operation at PKOP LLP.

Also in 2019, the electric energy generating capacities, drives - a turbo expander and a steam turbine generator were put into operation in the enterprise's modernization units.

The total amount of generated (produced) renewable energy broken down by sources for 2019 was:

- Power generation by solar panels - 12,654 kWh.

- Generation of power energy by thermo energy generators - 86,733,000 kWh.

- Generation of power energy from wind-solar generators for lighting fixtures (10 pcs.), each lighting fixture with a capacity of 100V (with 8 hour consumption (night) average production of 0, 330kWh).

2.3 Protection of atmospheric air

Within the frames of the State Program for Industrial and Innovative Development of the Republic of Kazakhstan for YY2015-2019, the construction of new process units was completed at PKOP LLP. Commissioned facilities have an environmental effect aimed at reducing the environmental emissions.

- In July 2017, the isomerization unit was launched with the output of fuel of К4 and К5 classes. When using fuels of К4 and К5 classes, emissions of sulphur dioxide to the atmosphere are reduced; it leads to improvement of the environmental situation in the region as a whole.

- A Wet Flue Gas Scrubber (Flue Gas Combustion) System (BELCO) is available at the RFCC Heavy Residue Catalytic Cracking Unit (1,000) with a capacity of 2,000 thousand tpa on the flue pipe DO -1014 (Wet Gas Scrubber). BELCO's EDV waste gas wet cleaning technology is designed to reduce particulate matter and SOx in emissions of catalytic cracker with treatment coefficient of 98%.

- Tank farms (tit. 3600) were built taking into account the reduction of limit hydrocarbon emissions, as they are equipped with a floating roof and a nitrogen cushion which captures vapour emissions by 95%. A line is provided for for pump units to return product to the tank farm with the installation of a control safety valve to maintain a minimum flow.

The entire technological process is ensured by strict observance of the process mode, with prevention of environmental incidents and compliance with technological control norms specified by the technological instructions and technological regulation.

- The sulfur production unit with a capacity of 4 thousand tons per year was put into operation. The unit is aimed at utilization of acid gases previously burned on a flare, with the production of sulfur with a purity of more than 99.9% by weight. In connection with the commissioning of SPU-4000 tn. emissions of sulphur dioxide (SO2) into the atmosphere decreased by 21%.

- Within the frames of the 2 stage of modernization, SPC (sulphur production complex) with a capacity of 15,000 tons/year was put into operation. The unit is aimed at utilization of acid gases previously flared with the production of pure sulfur with a content of 99.9 wt%. Due to commissioning of the SPC, emissions of sulphur dioxide (SO2) into the atmosphere decreased by 48%. Due to commissioning of the SPC, emissions of sulphur dioxide (SO2) into the atmosphere decreased from 1,476 tons. up to 710 tons.

- Oil-products on-spot loading unit was put into operation in CTG. Emissions of volatile hydrocarbons into the atmosphere during filling decreased upon commissioning of the Light oil-products On-spot loading. The proportion of volatile hydrocarbons decreased by 7%.

- In order to reduce discharges of oil products with drainage water and improve the operation of the enterprise's sewerage networks, a pilot version of an automatic drainage system has been introduced with an integrated system of preliminary separation of tank drainage waters into a hydrocarbon component and water, which has proven itself on the positive manner.

- Within the frames of the modernization, new treatment facilities were put into operation. This led to increase in the capacity of the Refinery's treatment facilities and improvement in the quality of wastewater treatment.

Additional treatment of effluents at the reverse osmosis unit saves fresh water up to 1.5 million m3 per year. The erected equipment is sealed, which allows to reduce emissions of pollutants and stench into the atmosphere. Upon removal of pollutants to the deodorization unit. Upon introduction of new sealed facilities, emissions of limit and unsaturated hydrocarbons from the Refinery's treatment facilities decreased by 17%.

Due to completion of the work on the modernization of treatment facilities, the efficiency of treatment of industrial wastewater for oil products and suspended substances was improved from 76% to 98%, which reduces the environmental burden by reducing emissions to the environment.

Specific emission of pollutants at PKOP LLP

| Oil-refining, t/1,000 t. of crude oil processed | Y2017 | Y2018 | Y2019 |

| 3,7 | 3,7 | 2,6 |

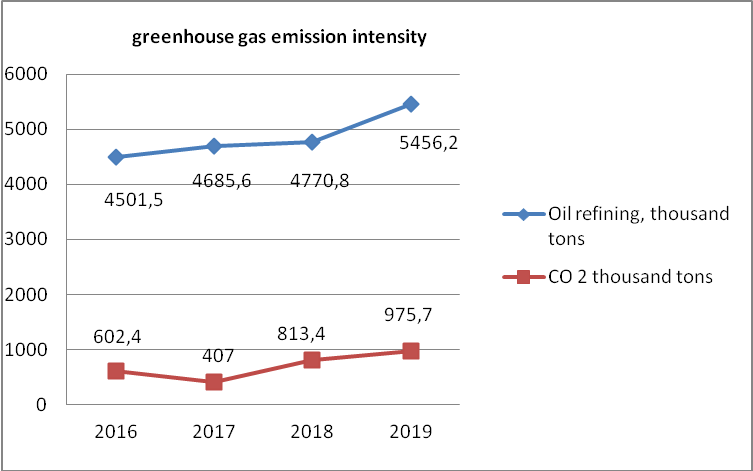

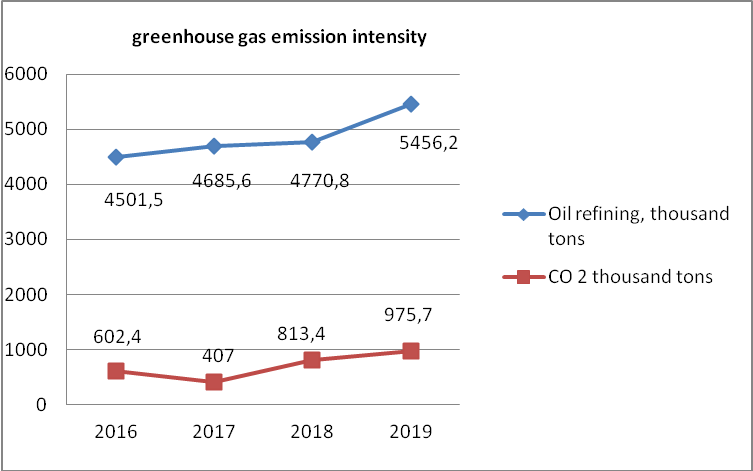

2.4 Greenhouse Gases

Climate change and greenhouse gas emissions

The climate change has become one of the most important challenges facing humanity in recent years. The climate change affects both people and natural systems, and can lead to significant changes in resource use, production and economic activity.

At PKOP LLP, the control of atmospheric emissions from stationary sources is regulated in accordance with the requirements of the Environmental Code of the Republic of Kazakhstan. PKOP LLP supports the state policy on global mitigation, commitments regarding greenhouse gas emissions, as well as the strategy of developing the renewable energy sources and environmental impact reduction, which contribute to the accelerated transition of enterprises to a “green economy” and the principles of the best available technologies.

Greenhouse gas emissions

Every year, PKOP LLP carries out greenhouse gases (GHG) inventory. The GHG inventory report and plant certificate shall be verified, and the GHG emission monitoring plan shall be validated by an accredited independent body. Based on the results, we receive a positive expert conclusion.

A verified report on greenhouse gases inventory is registered in due time with the Environmental Regulation and Supervision Committee (ERSC) of the Ministry of Ecology, Geology and Natural Resources of the Republic of Kazakhstan.

Greenhouse gas emissions:

| Greenhouse gases | Y2016 | Y2017 | Y2018 | Y2019 |

| СО2, Ktons | 602,4 | 716,4 | 813,4 | 975,7 |

| CH4, equivalent to Ktons of СО2 | 0,312 | 0,407 | 0,444 | 0,504 |

| N2O, equivalent to Ktons of СО2 | 1,49 | 6,01 | 3,29 | 4,29 |

2.5 Use of water resources

PKOP LLP strives for rational use of water resources. On July 1, 2019 KazMunayGas officially announced its intention to contribute to the conservation of water resources of the Republic of Kazakhstan. PKOP LLP reaffirmed its commitment to rational water resources management (8 water principles of KMG). This initiative was supported by the CEOs of PKOP LLP.

Technical water supply at the refinery is provided from three water supply sources:

Водоснабжение технической водой на НПЗ осуществляется с трех источников водоснабжения:

- The first source of technical water is Water Resources- Marketing LLP, i.e. quality of drinking water.

- The second source of water supply for technological needs of the refinery is water from own wells (own water intake), according to the Permit for production of industrial and technical underground water Series KG and N #007 dated 24.08.2011.

- The third source of water supply with technical water since 2016 is MC Ontustik SEZ JSC. Technical water is supplied to the refinery through water ducts of MC Ontustik SEZ JSC.

| Water consumption for the company’s own needs/hydrocarbon processing, m3/t of processed hydrocarbons (t.p.): | Y2017 | Y2018 | Y2019 | |||

| 0,64 m3/t | 0,45 m3/t.p | 1,06 m3/t | 0,74 m3/t.p | 1,08 m3/t | 0,76 m3/t.p | |

Water disposal at PKOP LLP:

Production facilities of the refinery have the following sewerage systems: household and domestic sewage system, production and storm waste waters. The refinery has two production and storm waste waters:

I system - for disposal of oil-containing neutral production and storm waste waters

II system - for disposal and treatment of emulsion and chemically contaminated waste waters containing crude oil, oil emulsions, salts, reagents and other organic and inorganic substances

Neutral oil-containing effluents from new process units, such as bottom water, washing water, storm water, process condensate are discharged into the first system of production and storm wastewaters.

Chemically contaminated effluents, blow-down effluents, ultra-filtration wastes from water treatment plant, and stripped acid waste waters are discharged into the second system of production and storm wastewaters.

Waste water of I and II systems undergo separate parallel mechanical and physical-chemical treatment in grit catchers, oil traps, radial-flow settling tanks and flotators. The treatment facilities are designed for treatment of effluents contaminated with oil products and suspended substances.

The receiver of production waste water of the Refinery PetroKazakhstan Oil Products LLP is an evaporation pond located in Ordabassy region of Turkestan oblast. The site of the evaporation pond is a land plot 13-15 km to the south-east of Arys. The site is located 5-7 km to the south of Yntymak village in sparsely populated desolate area.

Three different-level evaporator ponds are separated by uniform bulk earth dams. The area of water surface of evaporator ponds is 78.22 hectares. Including the first pond - 16.0 hectares, the second pond - 25.72 hectares and the third pond - 36.5 hectares.

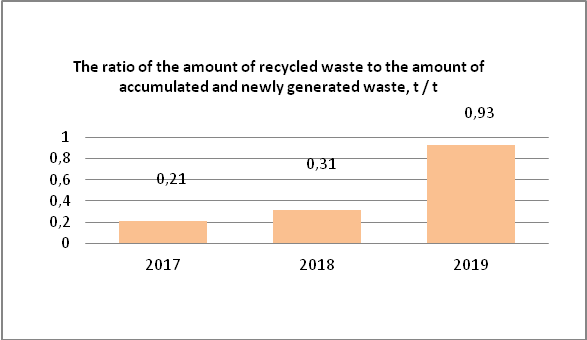

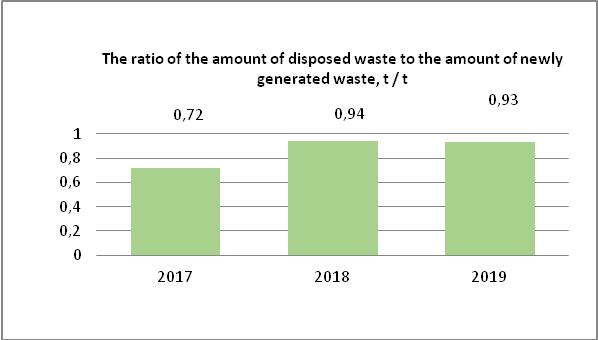

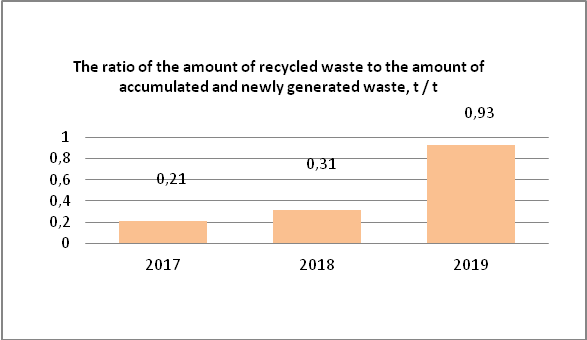

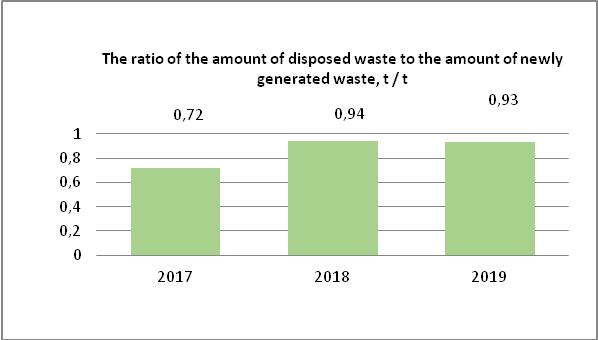

2.6 Waste Management

In order to comply with the requirements of the legislation in PKOP LLP in 2019 the Waste Management Program, agreed with the state bodies in the field of environmental protection, was developed and implemented. Significant cash is allocated on an annual basis and investments are identified to address waste generation issues.

Following the requirements of the environmental legislation of the Republic of Kazakhstan, the hazardous wastes, which cannot be neutralized, recycled, and disposed at our facilities, are transported to specialized landfills. Control over the contracting organizations is exercised with respect to fulfillment of the requirements by them on safe transportation, disposal and management of wastes.

The purpose of PKOP LLP is to dispose of contaminants in the most efficient and environmentally safe manner. The mandatory condition is the absence of secondary contamination from the process of processing historical contaminants. For this purpose, PKOP LLP plans to attract only responsible, well-equipped specialized companies capable of introducing and using the most modern safe technologies for processing oil wastes. The processing technology used by the contractor in 2018 is a thermal method (waste incineration method in special furnaces).

Currently, PKOP LLP processes oil slurries at decanter plant (sludge dewatering) with extraction of oil products, water with subsequent return to production cycle and separation of mechanical impurities.

Use of methods and technologies for processing and disposal of hazardous wastes directly at the refinery, which allows reducing the risks at their displacement to the landfill or disposal place of contractors.

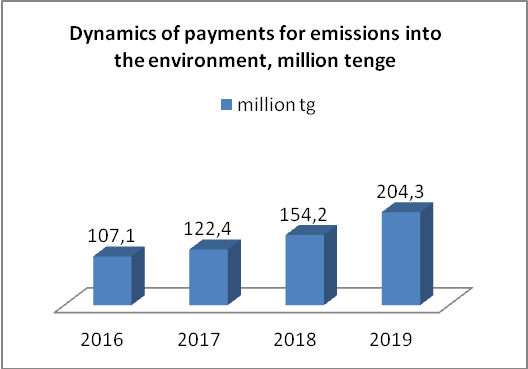

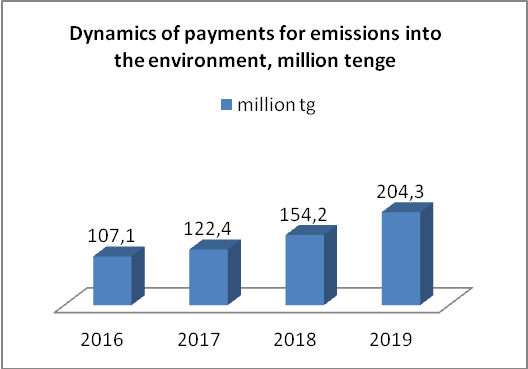

2.7 Financing of environmental activities

PKOP LLP carries out its production activities in accordance with the requirements of the environmental legislation of the Republic of Kazakhstan and implements the measures with a view to minimizing the environmental impact. Annual costs for environmental protection measures amount to more than a billion tenge.

PKOP LLP has implemented the projects on energy efficiency and energy saving improvement, in accordance with the approved Program for 2016-2020, implements measures according to the Environmental Management Plan agreed with the Ministry of Energy of the Republic of Kazakhstan. The dynamics of annual increase of company’s investments in the implementation of environmental measures is kept track of.

At the same time, it should be noted that with the growth of production, the increase in crude throughput and the commissioning of new modernization facilities, the environmental emissions haven’t increased. This is due to the fact that the commissioned facilities of the enterprise meet the requirements of “green technologies” and “green economy.”

Under the modernization project, PKOP LLP has completed the construction of new process units. The construction of the RFCC catalytic cracking complex for processing of mazut and vacuum gas oil with a capacity of 2.0 million tons per year to produce high-octane motor fuels has been completed.

PKOP implemented the modernization project in two stages. At the first stage, the production of motor fuel of environmental classes К4 and К5 (analogues of Euro-4 and Euro-5) was set up, according to the requirements of the Technical Regulation of the Customs Union. Construction of the Isomerization unit with a capacity of 600 thousand tons per year was completed. In July 2017, the Isomerization unit was launched with the output of fuel of К4 and К5 classes. The second stage of modernization is intended to increase the capacity of the unit to 6 million tons of oil per year and the depth of oil processing. At this stage, the arsenal of the enterprise was enlarged by the RFCC Catalytic Cracking Unit, “Prime G +” Gasoline Hydrotreatment, Saturated and Unsaturated LPG Sweetening Unit “Merox”, Hydrogen Treatment and others.

Within the framework of the program, the Sulfur Production Unit with a capacity of 4 thousand tons per year was put into operation in December 2015. Also, the company completed the work on modernization of treatment facilities. This activity allowed increasing the capacity of the refinery treatment facilities and improving the quality of wastewater treatment. Additional wastewater treatment at the Reverse Osmosis Unit allows saving fresh water up to 1.5 mln. m3 per year. At the same time, the air pollutant emissions from the treatment facilities are reduced to 90%, since all equipment is hermetically-sealed.

After the completion of the “Plan of Measures for Rational Use and Saving of Water Resources of PKOP LLP for 2017-2021”, including the modernization projects of the Circulating Water Supply Block and Treatment Facilities, the reduction of fresh water consumption for makeup of recycling systems amounted to 30-35%. The reduction of water consumption by the modernization facilities amounted to 9% of the total water consumption.

There have been no excess payments for environmental emissions during the reporting periods.

2.8 Environmental impact assessment

In accordance with the precautionary principle (Principle 15 of the Rio Declaration on Environment and Development of the United Nations, 1992), as well as requirements of the environmental management system of NC KazMunayGas JSC and provisions of legislation of the Republic of Kazakhstan at the stage of planning of each project, the environmental impact assessment (EIA) is carried out to determine the environmental and other consequences of options of management and business decisions made, to make recommendations on environmental enhancement, to prevent the destruction, degradation, damage and depletion of natural environmental systems and natural resources.

Within the frames of the State Program on Industrial and Innovative Development of the Republic of Kazakhstan for YY2015-2019, the construction of new process units was completed at PKOP LLP. Commissioned facilities have an environmental effect aimed at reducing emissions to the environment.

Environmental impact assessment was carried out on the basis of the analysis of the current situation of the PKOP LLP refinery, the adopted organizational and technical decisions, as well as in accordance with the Environmental Code of the Republic of Kazakhstan and the current regulatory and methodological documents of the Republic of Kazakhstan.

Conclusion (positive) on the project “PKOP LLP Shymkent Refinery Modernization and Revamping. Correction” from “State Expertise” RSE #01-0429/19 dated 24.10.2019.

PKOP LLP has set up the positive communication with the public of the city population located near to PKOP LLP. Joint participation in assembly and public meetings. Complete information is provided on the arising issues. A production excursion for the representatives of the public, elders, aksakals and labor veterans near the settlements - Karabastau and Voroshilovo are held.